GeoQ Products

At GeoQ, our array of geosynthetic products is curated to meet the diverse needs of Australia’s construction and environmental management sectors.

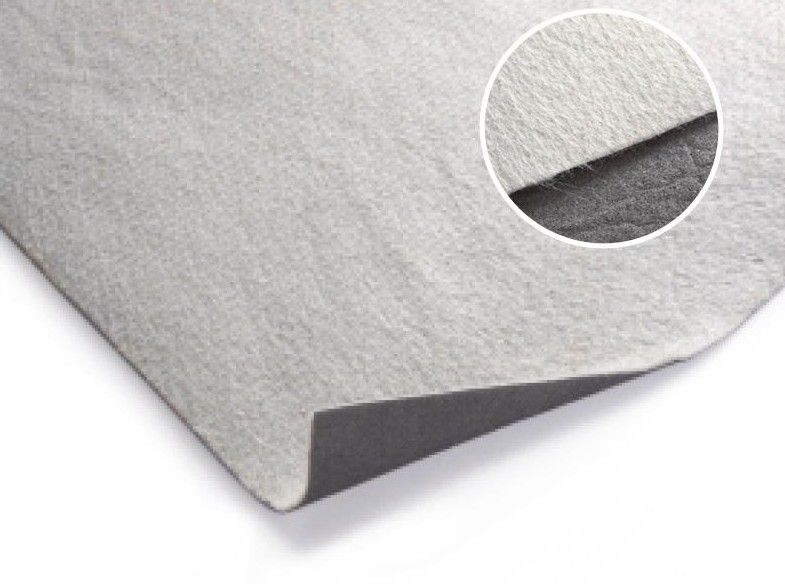

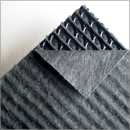

Our portfolio includes a comprehensive selection of liners, geomembranes, geotextiles and other geosynthetic products essential for ensuring the structural integrity and durability of a wide range of infrastructure projects.

Each product is chosen for its quality, performance and ability to meet stringent industry standards, reflecting our commitment to providing materials that not only serve their purpose but also contribute to the longevity and safety of the projects they’re a part of.